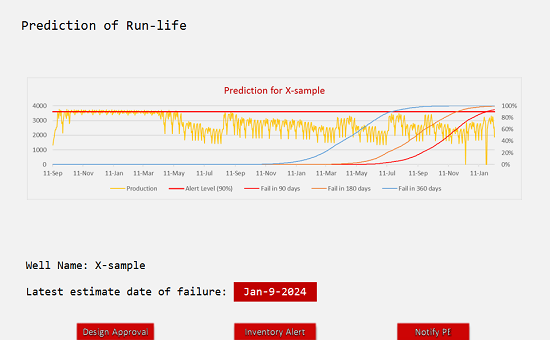

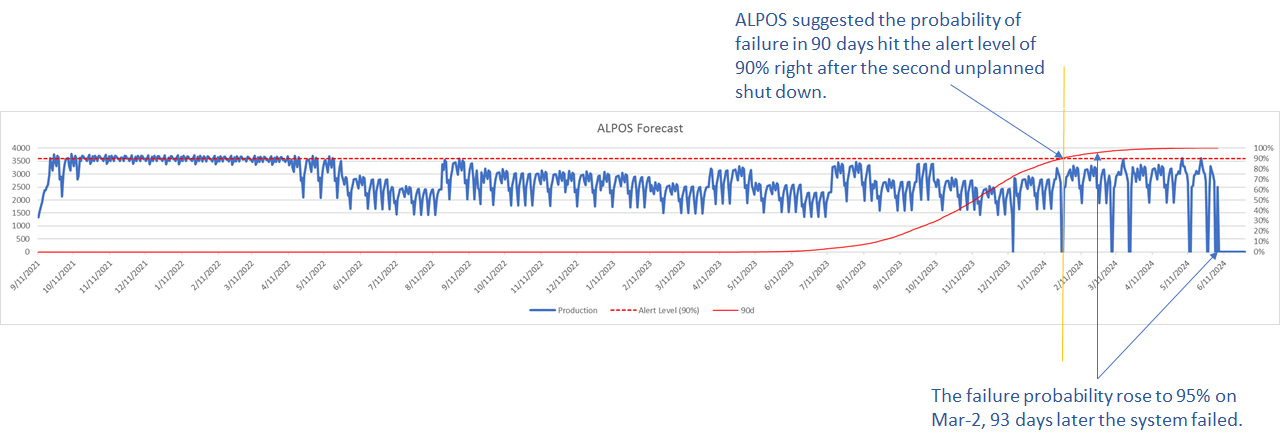

The most distinguished feature of ALPOS is failure prediction, it will allow us to see what’s most likely to happen in near future with monitored wells, so either we can try to optimize or get ourselves ready for a replacement.

Why we need prediction?

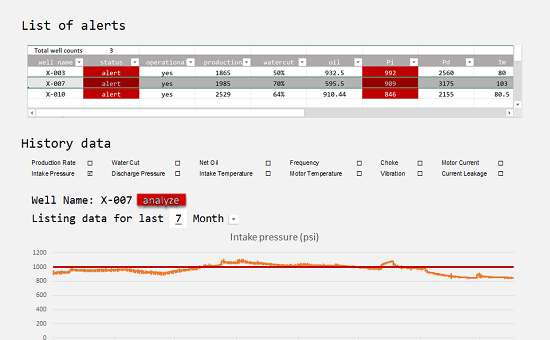

Short answer is to minimize down time related to replacing the artificial lifting system. The common practice is when one well fails, ESP operator gets a call out, and then troubleshooting, redesign, wait for the design to be approved, prepare for replacement, wait for hoist/rig. Minimum down-time of one well starts at 7 days, most of the down time is on “waiting”. We can try to eliminate all other wait times with other features of ALPOS, but there is one thing out of our control – hoist/rig schedule. If we can get our failed well on next week’s schedule we consider ourselves lucky enough. If two or more wells fail in the similar period of time and they belong to the same operator, the wait time would be a nightmare. But it doesn’t have to be that way. With the failure prediction algorithm, ALPOS will identify the probability of the failure in 3 months, 6 months and 1 year. If the figure reaches 80% for the well expected to fail in 3 months, considering other parameters ALPOS would likely to give out the suggestion to elective pull and put it on the nearest/non-colliding schedule to help the company better planning with their asset.

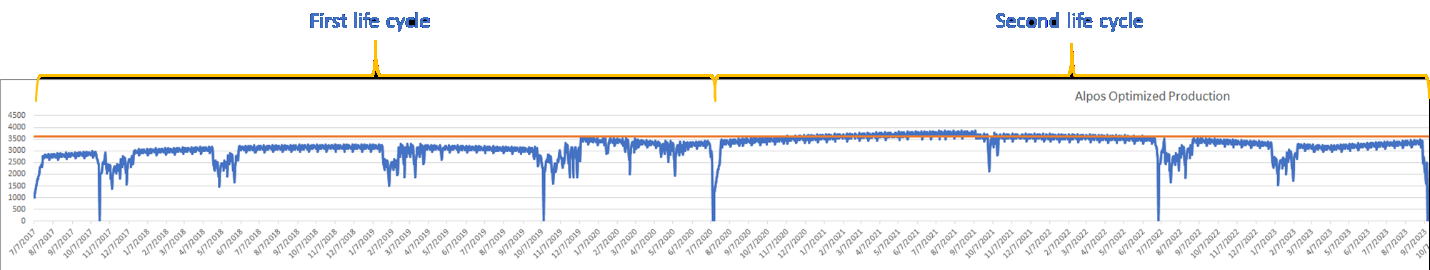

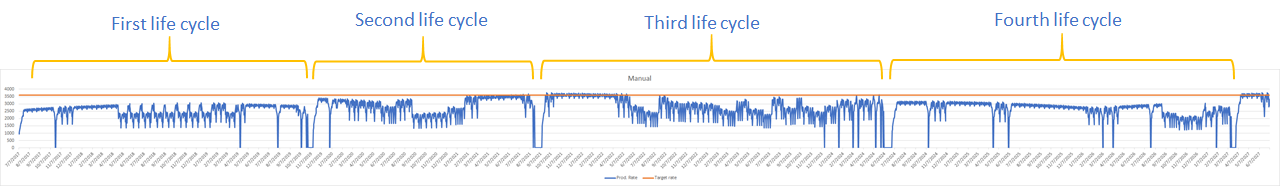

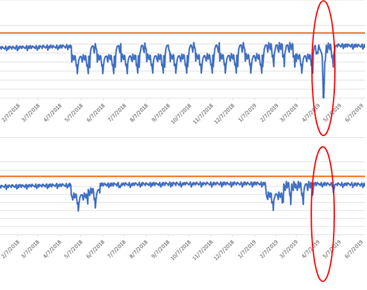

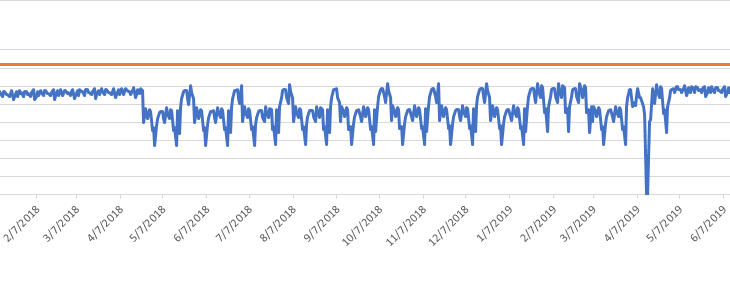

In the above example, the system suffers a lot from the fluctuation and when it comes closer to the end of its run-life, the well unplanned trips for multiple times. Base on the algorithm of ALPOS, by Mar-2 ALPOS will identify the chance of failure in 3 months for this well to be as high as 95%. So, if this alert can be handled properly, the potential one month (multi-million dollars worthy) down-time due to multiple colliding/short of stock could be prevented.