There are multiple reasons for unplanned shutdown: under load, over load, over current, over heat, etc. For each particular reason, there could be a way to proactively response. However, what happens very frequently now is that in order to protect the system from get itself burnt, it is very often chose to trip the well rather than solutions with better result.

Impact on run-life

With unplanned shutdown we put the impact on run-life before the loss of production, because when unplanned shutdown happens, very often it becomes a life/death situation. For every complete shutdown, the damage to the mechanical and electrical system is hundreds of times worse than the fluctuation.

i) Mechanically, every time the system restarts, it not only tests the shaft, connections and bearings etc., and also courses tiny fractures on those items, which will lead to shortening run-life.

ii) Foreign object, when a well trips. If there is foreign object like sands presence in the tubing, it will sit above the discharge of the pump. When the system restarts, it is always a challenge blowing them off, very frequently we get repeating over-load. If the sand problem mixed with other object such as paraffin, an unplanned shutdown could mean a death sentence for the lifting system.

iii) Electrically, during those attempts of restarting the electrical system gets a lot of surges, the load is very common built up to more than 150% of its capacity which will course severe damage.

Production loss

When unplanned shutdown happens it is obvious that the production will suffer loss, it’s just the matter of how much loss and the answer is depending on how long the shut-down will be. If it’s protective shut-down due to the settings, if lucky we’ll just need to wait for the operator to come to do the reset, if in environment like in Iraq this could means up to a week. If not lucky that could means failing to restart and waiting for a pull out.

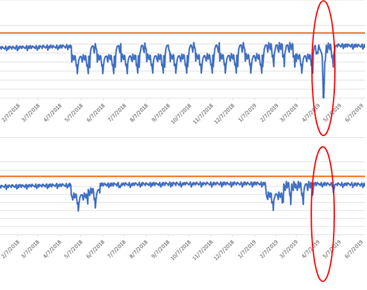

However, if a shutdown is beyond the control of ALPOS (i.e. power fluctuation/black out), a rapid restart is always recommended, not just for the sake of production but also to avoid the high failure rate of long time shut down, especially for those wells with problems like sand, paraffin etc. So, whenever those shutdowns happen, ALPOS will try to auto start the well remotely when the well gains power, those auto starts will be closely monitored by engineers on duty to make sure the artificial lifting system operates in its expected range. Under those circumstances, ALPOS will map out a restarting scheme considering the structures of the power grid to make sure the startups won’t trigger another failure to the Power Grid.

With above procedure, we don’t need to wait for the operators to manually start well by well. Combing with the unnecessary shutdown ALPOS help to avoid, the total downtime is expected to be minimized to a very low level (10% of current average).