Design compatibility has a huge impact on both run-life and production, it is believed to be equally important to the well condition impact and equipment overall quality (manufacturing, installation and daily management). So, it’s unarguably important.

Even though we have very advanced tools and knowledge to make compatible design these days, it is still very common that when one system is installed it could not perform under its best range. The reasons contribute to this fact includes, inadequate latest well data, unavailability of designed items as well as human error. ALPOS is designed to eliminate all of those.

a) The number one task for ALPOS is to collect real-time data to feed back to the server and analyzing the performance to determine how things can be done differently in the next life-cycle where ALPOS could contribute to the design, so the design with ALPOS involved is well informed and data equipped.

b) With ALPOS monitoring one well, it would suggest the best design for the next cycle and update the design in case any new activity matters enough to trigger a change. In the meantime, working in conjunction with its life-prediction module, ALPOS will send out alert information to the client to inform the ESP operator to prepare replacement system according to the very specific design at least 3 month before the failure. This would avoid the circumstances when one well fails, and the suggested design is not available, so the “next best thing” available is installed. Very often, that “next best thing” will cost the company a high percentage of production loss and a confirmed shorter run-life.

c) Human error is preventable, and what ALPOS doing is that it will put out a suggestive design, and the Application Engineer working with ALPOS will overlook the design and choose to approve it or put up another design to override it. To choose to override, the AE is believed to have adequate information and strong confidence with which that version of design will outperform the ALPOS one, which means an error is very unlikely. Moreover, when override happens the performance in the next cycle will be monitored by ALPOS, if the result outperforms the ALPOS prediction then that human design will be injected into ALPOS as a calibration for the Design Algorithm of ALPOS.

With the help of ALPOS, what will be improved includes:

Performance

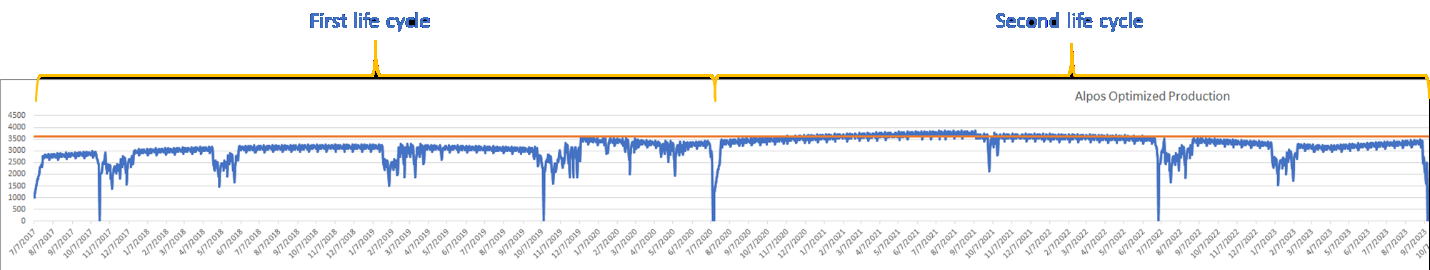

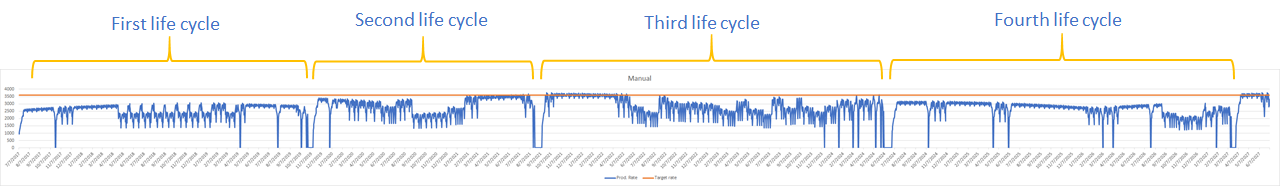

By comparing before and after the ALPOS redesign, we will find a significant improvement with the baseline of the production. 10%~15% on the production/target rate.

Consistency

With the help of “predict-alert” feature of ALPOS, it’s expected that for most of the failure, a suitable designed set of equipment will be in place for replacement.

So, what can be found in the current situation, like in the fourth life cycle when a non-compatible equipment was installed, the baseline of the production will move away from the target again.

With ALPOS in place, that situation will be strictly monitored and prevented.

Run-life

With compatible design, the run-life will be extended to a reasonable level and it would be a stable one when monitored under longer time span.

With ALPOS, the ARL (Average Run Life) will be 35% longer with joint effort of the design, fluctuation countermeasure and prevention of unplanned shut-down.